Ready Mix Concrete Supplier

Table Of Content

For example, M70, cement, sand (fine aggregate), and coarse aggregate are batched in volumes according to the design mix. Concrete mix design is the process of determining the ideal proportions of cement, aggregates, water, and admixtures to produce concrete with desired properties. Proper concrete mix design finds applications in various construction projects, including buildings, bridges, roads, and more. The benefits include enhanced structural integrity, reduced maintenance, and prolonged service life. Having the necessary resources when mastering concrete mix design for quality construction is essential. Depending on the project, the resources required may vary; however, several common resources are required for any concrete project.

ACI Web Pages

However, due to the variability of the mixed material, the nominal concrete for given workability varies widely in strength. However, the designed mix does not serve as a guide as it does not guarantee the correct mixing ratio for the prescribed performance. Since the amount of concrete required for construction is huge, the economy in the number of materials such as cement makes project construction economical. CalPortland also provides architectural and decorative concrete for aesthetic applications with high technical or color matching requirements.

Advantages of Using Nominal Mix Concrete over Design Mix Concrete

Ultra-high performance concrete: Mix design, raw materials and curing regimes-A review - ScienceDirect.com

Ultra-high performance concrete: Mix design, raw materials and curing regimes-A review.

Posted: Fri, 01 Dec 2023 04:13:05 GMT [source]

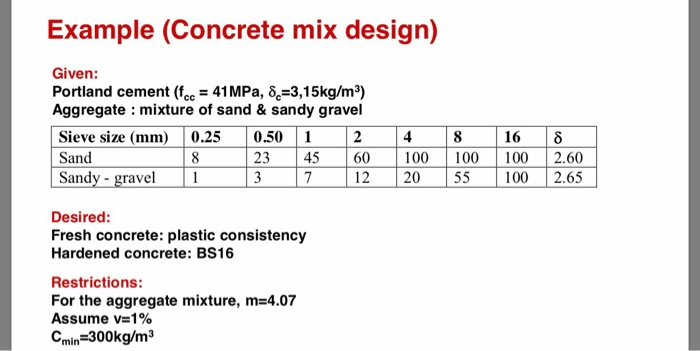

The calculated mix proportions undergo laboratory trials to ensure that they meet the desired performance criteria. Second, nominal mixed concrete may not meet the specific strength and durability requirements of certain applications. This is because the mix is not tailored to the construction project’s unique performance specifications. Nominal mix concrete is suitable for small-scale construction projects or in situations where specific performance requirements are not critical. Preliminary tests are conducted on the materials, and mix proportions are determined based on the desired properties. Combining the right materials in the right proportions and ratios is key to creating a concrete mix that produces excellent results.

Benefits of Concrete Mix Design

We produce sand, crushed rock and road base for construction sites, landscaping and home improvement. With locations throughout Southern California, we provide you with concrete for your residential, commercial and landscaping needs. Concrete house plans have exterior walls made of ICFs, concrete block, or poured concrete rather than stick framing, which is how the vast majority of homes are built.

How to Estimate Duration of Activities in Construction

Another important strategy for mastering concrete mix design is understanding the importance of testing. Testing should be done before, during, and after the concrete has been mixed and poured. Different tests should be done to determine the required properties of the concrete, such as strength, durability, air content, and water-cement ratio.

Nominal mix concrete, despite its simplicity, has several limitations that make it less suitable for large-scale or complex construction projects. The American Concrete Institute (ACI) method, British method, and Department of the Environment (DOE) method are among the most widely used approaches. Cement acts as the binding agent in concrete and holds all the other components together. Portland cement is the most commonly used type of cement in concrete production. It is a fine powder that, when mixed with water, undergoes a chemical reaction known as hydration, forming a strong and durable paste that binds the aggregates together. In this step, you determine the maximum size of coarse aggregate to be used in concrete.

CONCRETE VOLUME CALCULATOR and REQUEST A QUOTE

In nominal mixed concrete, the proportion of mixing concrete ingredients is fixed and recommended by standard codes. CalPortland produces high quality ready mixed concrete in all regional locations. Our products are designed for optimal performance for whatever your application requires.

Applications

In this article, we will discuss the importance of getting the right mix ratio for concrete. High-strength mixes provide ease and, under normal conditions, have a margin of strength above specified. Concrete with undemanding performance may only be used for very small jobs when the 28-day strength of concrete is 30 and does not exceed n/s. Nominal or standard mixes (determined in the code by the amount of dry material per cubic meter and slump).

Flexural capacity of eco-friendly reinforced concrete beams Scientific Reports - Nature.com

Flexural capacity of eco-friendly reinforced concrete beams Scientific Reports.

Posted: Fri, 17 Nov 2023 08:00:00 GMT [source]

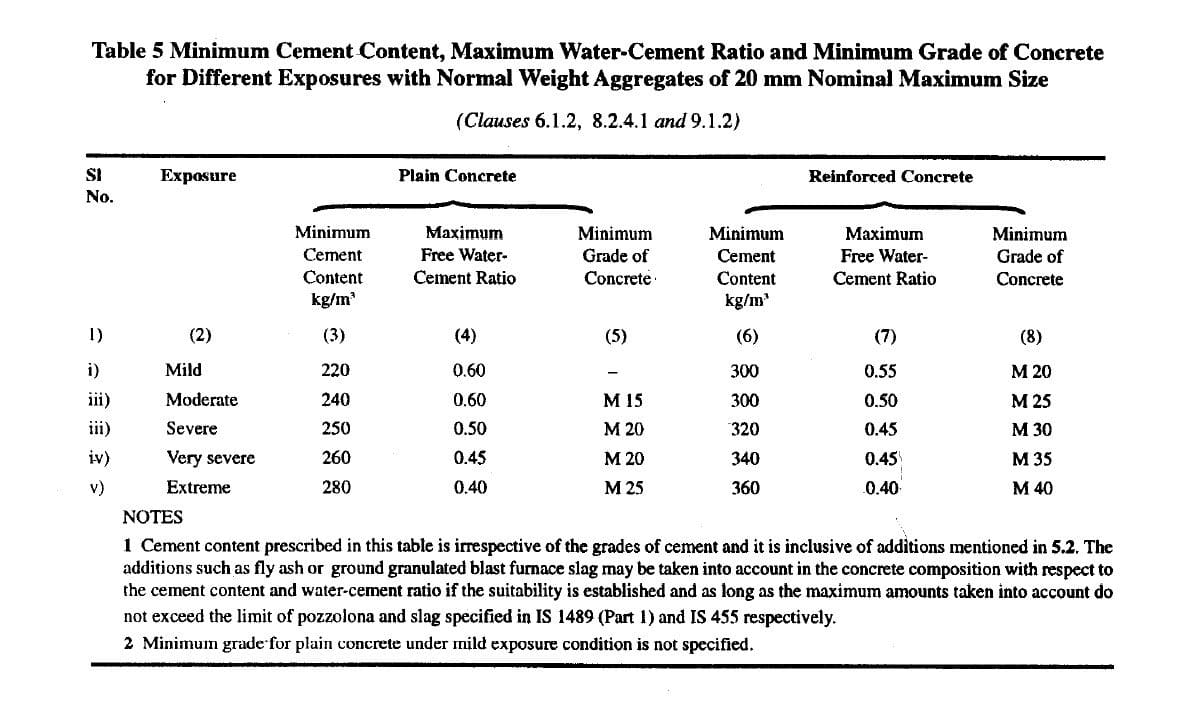

Previously, concrete specifications determined the ratio of cement, fine and coarse aggregates. The high strength mix ratio specifications for concrete stipulate these ratios of cement, sand, aggregate, and water. From the table above to the M45 grade, these concrete ratios are called nominal mix concrete. This is the standard mix ratio normally used for a small construction project where a grade of concrete is below M20 and quality standards are decent.

Mastering concrete mix design is an essential step in ensuring quality construction projects. It involves understanding the essential components of concrete mix design, creating mix designs according to specific needs, and establishing quality control processes. In addition, it is important to have a timeline and plan of action and the necessary resources, such as protective equipment and materials, safety measures, and knowledge and expertise. Design mix concrete is a more modern approach to concrete mix design compared to nominal mix concrete.

For contractors, understanding and mastering concrete mix design is essential for quality construction. With the right strategies, contractors can make the most of their concrete mixes and ensure that the end products meet their needs. Quality control is improved, work efficiency increases, and cost savings can be achieved.

Concrete mix design with an excessive water-cement ratio, larger maximum size could also be helpful. For this reason, minimal compressive strength included in many features, these mixes are known as standard mixtures. On the other hand, low humidity, low temperatures, and no wind can require less water. This means that the mix ratio for concrete in different weather conditions may vary, and it’s important to take this into consideration when planning and executing a project. However, there are several factors that can affect the mix ratio, and it’s important to understand these factors in order to achieve the desired results.

The unit weight and the yield are two additional factors that must be taken into account while trial mix proportioning. The yield is computed by dividing the total weight of all the components batched by the unit weight of the freshly mixed concrete. Finally, it is important to understand the importance of protecting the concrete from weather conditions. To ensure the long-term performance of the concrete, it is important to use waterproofing products, properly seal the concrete, and apply protective coatings. These measures should be taken before, during, and after the concrete has been mixed and poured. The strength of concrete varies from batch to batch depending on the variation in material quality, variation in mixing ratio, variation in batching and mixing equipment, etc.

This is the most rational approach to the selection of mixing ratios with specific materials taking into account more or less specific characteristics. However, Building Codes provide nominal and Standard Concrete Mix Ratio for various construction tasks based on experience and testing. These proportions will result in a concrete mix with the desired strength and workability. In the image below, the precise amounts of each ingredient are determined to create a quality design mix of concrete. Fine and coarse aggregate contents may be adjusted based on practical considerations to achieve workability.

We are capable of providing complete color services as well as other highly technical finishes for stamped concrete and design for environmental and architectural requirements. Concrete mix design can be optimized to reduce environmental impacts, such as carbon emissions and resource depletion, without compromising performance. Based on the desired strength and exposure condition, a water-cement ratio of 0.45 is selected for M30 grade concrete. Log in to TheConstructor to ask questions, answer people’s questions, write articles & connect with other people. This saves the cost of the project and an economical concrete mix can be obtained. Insufficient workability resulting from incomplete compaction can have a serious impact on the strength durability and floor finish of the concrete.

The first resource that must be obtained for any concrete project is protective equipment and materials. Proper protective gear, such as safety goggles, gloves, and hard hats, should be worn at all times to ensure the safety of all personnel working on the project. In addition, any materials and tools used to create the mix design must be of the highest quality and meet all applicable safety standards.

Comments

Post a Comment